HODW-O®

High Intensity UV with Fiber Optic Principles

Our system has revolutionized UV technology through a patented principle of UV disinfection, HODW-O® is a technology of disinfection and treatment of water, which maximizes the efficiency of dose delivery using less energy than other UV systems and with a larger size little. It provides 100% of the time an actual dose and not average, for continuous control of bio-fouling demonstrated. Thanks to its advanced engineering, based on optical fiber and hydraulics, the system has achieved validations and acceptances unmatched by any other commercially available UV technology.

100% Chemical Free

100% chemical-free disinfection (validated EPA virus 4-log and 5-log microbial). Disinfection occurs only with UV Medium Pressure.

Special Applications

Non-thermal pasteurization (FDA-MPO criteria); Lactose whitening; Disinfection of Syrup for Beverages, Recovery of Water of Cow ..., etc.

Dechlorination

Eliminates chlorine in industrial processes without the need to add chemicals such as Metabisulfite that causes anaerobic reactions.

Biofilm Reduction

Reduction of Biofilm in O.I membranes and Cooling Towers avoiding potential dangers such as Legionella hidden in amoebas.

Self Control

Integrated Software Able to self-regulate depending on the characteristics of the water and stop the production process due to contamination risk.

Monitoring

HODW-O® ™ equipment can be controlled remotely, either in main buildings or in remote areas without dedicated personnel.

Plug & Play

HODW-O® easily integrates with new or pre-existing installations. With qualified personnel, its installation and commissioning can be done in a few hours.

Automatic Reports

HODW-O® can be delivered with an automatic reporting system for those cases in which by legislation it is mandatory to keep a record of the disinfection treatment.

Our Medium Pressure UV lamps give more for less

- They give more disinfection per cm / inches than low pressure lamps.

- Broad germicidal spectrum that attacks different parts of the microorganism and destroys its repair mechanisms.

- There is no danger of rejuvenation of the microorganisms that compromise your product later.

- More efficient in the inactivation of viruses.

- Easily inactivates microorganisms resistant to other disinfection methods such as chlorine, heat and low pressure UV.

- It uses much less energy than low pressure UV systems to achieve the same results.

Less UV lamps are necessary to achieve a result equivalent to low pressure

- Less lamps means a significant reduction in maintenance.

In some cases, 2 or 3 Medium Pressure lamps can replace up to 50 Low Pressure lamps.

Works with cold and hot water, unlike low pressure UV rays

Medium Pressure UV Lamps

Less lamps provide better protection

Automatic Control of Water Transmittance in Real Time

One sensor per lamp measures critical data in real time

Automatic Control of the RED Dose in Real Time

One sensor per lamp measures critical data in real time

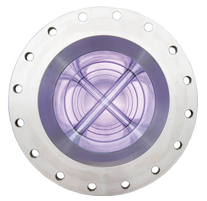

Window "Show-Me"

Safe window that shows the work system in real time.

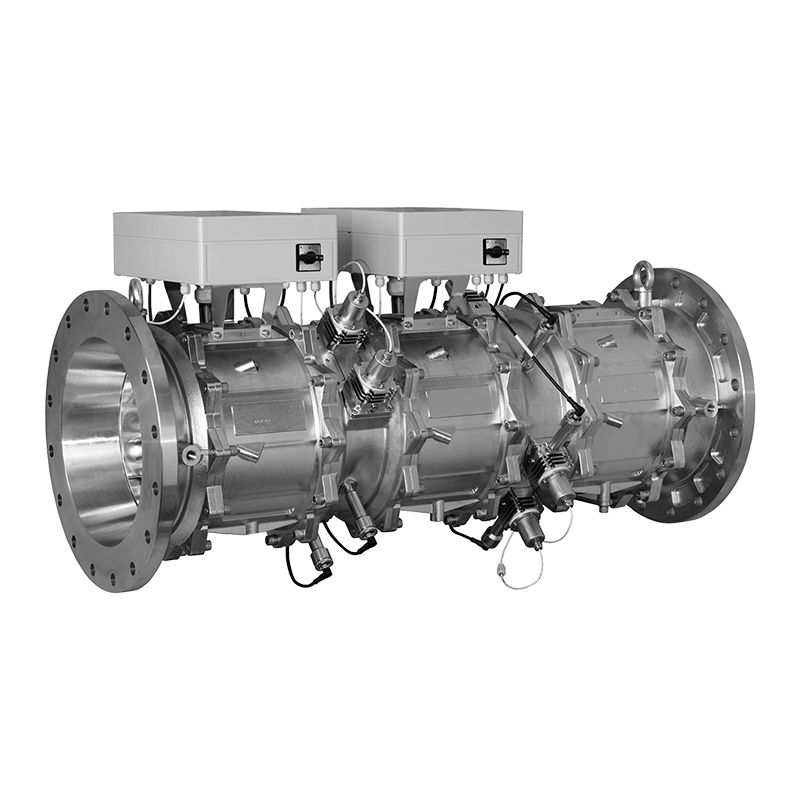

Quartz Camera that uses Optical Fiber Principles

Optimizes UV Efficiency to reduce energy costs through Photon Recycling

316 Steel Body

316 Electropolished Stainless Steel Cover that protects the air chamber and the body of quartz and other sensitive elements of the reactor.

Internal Thick Quartz Tube

More secure and better management of the lamp. Prevents accidental spillage of glass or mercury in the water flow.

HODW-O®

It has the ability to dose the rhythm of each lamp. The properties of its software of logic, sensors and controls, allow the automatic adjustment of the dose according to the evolution of the water quality to guarantee the protection in real time. The dose needed to meet any application need is maintained at all times through this reliable approach. The efficient use of UV energy, achieved through the properties of control of the frefuencia of the doses, allows a lower consumption of energy and a greater duration of the lamps.

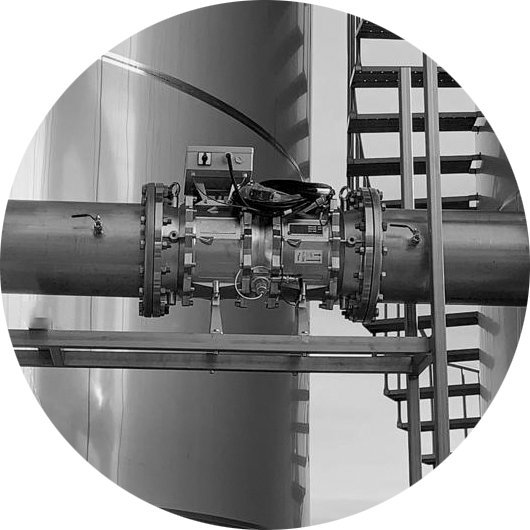

In the image you can see the cross section of the HODW-O® unit that shows the high level of disinfection achieved by the configuration of the quartz chamber, equipped with thick lampholder tubes that isolate these from the water.

HODW-O® lamps are shorter and reduce the risk of breakage

- Lamp with lengths of 26.3 cm (10.35 “).

- Easy to handle

Thick quartz tubes protect lamps and water

- Quartz chamber with 5 times the thickness of conventional quartz sleeves.

- There is no possibility of breaking glass or mercury in the water, in the unlikely event of a UV lamp breakage.

- There are no thin quartz sleeves that can break or replace.

Less mercury

- Its small size, involves less mercury and less exposure in case of breakage.

- Some systems use very long lamps that are much more susceptible to breakage. These lamps add the danger of large “spills” of mercury when they break.

RELIABLE AND EFFECTIVE TO ANY CHALLENGE

Thanks to excellent results in combination with an increasing specialization, we have been able to face with guarantees the application of the principles of HODW-O® to some market sectors where there is a need to avoid the use of chemical products and where a highly Effective disinfection method is especially important. The principles of HODW-O® are currently used by aquaculture, food and beverage companies, dairy industries, ships, and by municipalities for a wide range of applications such as supply through firebreaks, non-thermal pasteurization, post-GAC disinfection, drinking water and more.

A SOLUTION TO YOUR MEASURE

The HODW-O® systems include the disinfection unit, a ballast module configuration and controller. Water flows are managed without obstacles, resulting in a low pressure loss. The UV lamps have a fast MPHI connection inside a thick quartz tube that significantly reduces the risk of breakage and its consequences. A UV intensity sensor (UVIS) provides continuous measurement of the output of each lamp. In addition, a UVT analyzer informs and tracks the water quality and a window with UV protection allows you to see the interior in operation. An optional cleaning system cleans the surface of the quartz tubes automatically.

INDIVIDUAL EQUIPMENT – SKID SYSTEMS

Our UV systems adapt to any type of installation, for this we have created a wide range of models and solutions in Skid in order to meet the market demand, as well as its applications. All our systems comply with the following regulations, among others:

• 4 log EPA virus and 5 log microbial inactivation

• Disinfection of water / water equivalent pasteurized by the FDA

• European Low Voltage Directive (LVD): 73/23 / EEC (electrical safety)

• EC / 99/93 (quality of water for human consumption)

• Quality management ISO 9001: 2008

• United States Federal Performance Standards 40 CFR 141.720

• GOST Standards Institute, Russian Federation

• National Institute of Public Health, Poland

• Exempt Resolution No. 2.327 of December 31, 2010, within the framework of the General Law of Fisheries and Aquaculture

• CE compliant

• Biocompatible materials are used in any part of the body that is in contact with water to avoid irritation, sensitization and toxicity

REQUEST TECHNICAL-ECONOMIC PROPOSAL

“ULTRAVIOLET DISINFECTION”

HODW-O®

Specialized Media where you can find information related to Water-On activities and technologies.